Purification of degummed crude sunflower oil with selected metal-organic frameworks as adsorbents

E. Yılmaza,* and A.K. Erdena

aÇanakkale Onsekiz Mart University, Faculty of Engineering, Department of Food Engineering, 17020, Çanakkale, Turkey

*Corresponding author: eyilmaz@comu.edu.tr

| |

SUMMARY

The aims of this study were to investigate the effectiveness of seven metal-organic frameworks (MOFs) as adsorbents for the purification of crude degummed sunflower oil, and to compare their effectiveness with three natural clays. The oil was treated with two different addition levels (0.05% and 0.3%, w/w), and two different treatment times (0.5 h and 3.0 h) under constant temperature (25 °C). The results indicated that all adsorbent treatments improved the oil’s physico-chemical properties. Most importantly, the oil’s free fatty acid, peroxide and p-anisidine values were significantly reduced by Ti-MOF and γ-CD-MOF in comparison with the control sample. The oil showed no contamination by the metals during the MOF treatments. There were no significant changes in the fatty acid or sterol composition of the treated oil, while α-tocopherol contents decreased to some extent. This study proved the possibility of MOF as adsorbents for crude oil purification, and showed the great potential of Ti-MOF and γ-CD-MOF as promising adsorbents.

|

| |

RESUMEN

Purificación de aceite de girasol crudo desgomado mediante estructuras metal-orgánicas seleccionadas como adsorbentes. Los objetivos de este estudio fueron investigar la efectividad de siete estructuras metal-orgánicas (MOFs) como adsorbentes para la purificación de aceite de girasol crudo desgomado y comparar su efectividad con tres arcillas naturales. El aceite fué tratado adicionando dos cantidades diferentes (0,05% y 0,3%, p/p) y dos tiempos de de tratamiento (0,5 h y 3,0 h) a temperatura constante (25 °C). Los resultados indicaron que todos los tratamientos con adsorbentes mejoraron las propiedades físico-químicas del aceite. Más importante aún, los valores de acidez libre, peróxidos y p-anisidina se redujeron significativamente con Ti-MOF y γ-CD-MOF en comparación con la muestra de control. Los aceites mostraron no haberse contaminado con los metales durante los tratamientos de MOFs. No hubo cambios significativos en las composiciones de ácidos grasos y esteroles de los aceites tratados, mientras que los contenidos de α-tocoferol disminuyeron a cierto nivel. En consecuencia, este estudio demostró la posibilidad de que los MOFs sean adsorbentes para la purificación de aceites crudos, y demostró el gran potencial de Ti-MOF y γ-CD-MOF como adsorbentes.

|

1. INTRODUCTIONTOP

The sunflower (Helianthus annuus) is the fourth largest oilseed crop produced worldwide. It contains about 40% oil, and sunflower oil provides around 12% of the world’s oil supply (Davidson et al., 1996). Sunflower oil was the major edible oil in the Turkish market in 2016 with a total production of 513.000 tons. In the same year, Turkey imported around 702.000 tons of crude sunflower oil and 185.000 tons of sunflower seeds, and consumed 774.000 tons of refined-winterized liquid sunflower oil, and exported around 601.000 tons of refined liquid sunflower oil. It was also stated that sunflower oil was the most used vegetable oil in trade and consumption among all vegetable oils in Turkey, except for olive oil (Anonymous, 2018). Oil is extracted from sunflower seeds with expeller presses, with solvents or with press and solvent combined systems. In Turkey, the oil is usually extracted from non-dehulled seeds with press and solvent combined systems. Further, mid- and high-oleic cultivars are preferred and produced in Turkey (Anonymous, 2018; Nas and Gökalp, 2017).

Refined sunflower oil is a good vegetable oil with a bland taste and visibly appealing with a light yellow color. Depending on the cultivar, it contains high amounts of polyunsaturated fatty acids, and around 45 mg α-tocopherol/100 g oil, which is the highest among all leading vegetable oils. The specifications for refined sunflower oil are iodine number of 130–144 gI/100 g oil, saponification number of 188–194 mg KOH/g oil, refractive index of 1.4740–1.4745 (at 25 °C), smoke point of 252–254 °C, unsaponifiables of 1.5% maximum, peroxide value of 2.0 meq/kg, and free fatty acidity of 0.05% maximum. Its major fatty acids are given as 3.0–10.0% palmitic acid, 1.0–10.0% stearic acid, 14.0–65.0% oleic acid, 20.0–75.0% linoleic acid (Davidson et al., 1996).

Since crude sunflower oil is not acceptable for consumers due to its harsh taste, dark color, possible solvent contaminations and other unhealthy components, it is refined successively by degumming, neutralization, bleaching, dewaxing, and deodorization processes. Sometimes, physical refining is used after degumming plus bleaching and deodorization unit operations (Davidson et al., 1996; Nas and Gökalp, 2017). Regular bleaching or any type of adsorbent treatment of oils has been an indispensable process, and various natural or synthetic adsorbent materials have been researched for this purpose. Fuller’s earth, natural montmorillanite-attapulgite clay, amorphous silica, various zeolites, active carbon, sepiolite and others have been used as bleaching clays for crude oil refining (Hodgson, 1996; Davidson et al., 1996; Nas and Gökalp, 2017; Bulut and Yilmaz, 2010). Metal-organic frameworks (MOFs) as adsorbent materials for oil refining were recently introduced in one study (Vlasova et al., 2016). MOFs were defined as laboratory synthesized materials constructed by joining metal-containing units with organic linkers (ligands) through strong bonds by reticular synthesis. They are open crystalline frameworks with permanent porosity, regular cavities, dynamic flexibility and aesthetic structures. Hence, MOFs provide enormous surface and pore properties, and they are very suitable materials for gas adsorption and storage, separation, sensors, analysis, luminescence, magnetism, drug delivery, and selective adsorption applications (Stock and Biswas, 2012; Furukawa et al., 2013; Ma et al., 2014). A review summarizing the current state of the art in the use of MOF as solid catalyst with versatility and flexibility for various reactions was published (Dhakshinamoorthy et al., 2018).

There is a limited number of studies on MOF applications in edible oil purifications. In one of them (Li et al., 2015), MIL-101 MOF was used to selectively adsorb some herbicides from soy, sunflower, corn and peanut oils. In the other one (Vlasova et al., 2016), MIL-53 (Al), Zn-MOF and MIL-125 (Ti) MOFs were used to refine crude vegetable oil, and were shown to have the ability to adsorb and remove free fatty acids, peroxides and color pigments from the oils. To the best of our knowledge, there is no other study reporting the application of MOFs in edible oil bleaching or purification.

In this study, seven laboratory-synthesized MOFs and three natural clays were used as adsorbents against a control sample in the purification of crude degummed sunflower oil. This study differs from the study of Vlasova et al., (2016) in two aspects: firstly, in this study, seven different MOFs were tested, and secondly, the MOFs were compared with three natural clays (commercial bleaching earth, natural zeolite and sepiolite) under the same conditions. Further, a recycling study of up to five times with the best performing adsorbents was carried out to observe the re-usability of the adsorbents. Hence, this study is novel and may encourage further studies with various other MOFs or newly constructed MOFs for the purpose of crude edible oil refining.

2. MATERIAL AND METHODSTOP

2.1. MaterialsTOP

Degummed crude mid-oleic sunflower oil (5 kg) was provided by Trakya Birlik Oil Processing Factory (Tekirdağ, Turkey). Natural zeolite, natural sepiolite and commercial bleaching earth were donated by Rota Mines Co. (Istanbul, Turkey), Madkim Coal and Chem. Co. (Istanbul, Turkey) and Trakya Birlik Oil Processing Factory (Tekirdag, Turkey), respectively. The natural zeolite and sepiolite were acid-activated in the laboratory by mixing with nitric acid (0.1 M) at a 1:10 (w/w) ratio and heating at 60 °C for 4 h before filtration and washing with pure water until the pH of the filtrate reached 6.0. Activated clays were dried at 110 °C to full dryness under the hood. Commercial bleaching earth was already activated and used as received.

Seven different MOFs were selected based on their suitability and safety knowledge for food process applications, and synthesized in our laboratory following the given procedures in the literature. The MOFs were: 1) the titaniumbutoxide-terephthalate MOF (Ti-MOF) synthesized following the method of Vlasova et al., (2016); 2) gamma-cyclodextrine-potassium hydroxide MOF (γ-CD-MOF) synthesized according to Moussa et al., (2016); 3) chrome nitrate-terephthalate MOF (Cr-MOF) synthesized by the method of Li et al., (2014); 4) aluminum-MOF (Al-MOF) synthesized according to Ma et al., (2014); 5) zinc nitrate-2,5-furandicarboxylic acid-MOF (Zn-MOF) synthesized following the solvothermal reaction given in Bu et al., (2012); 6) magnesium-MOF (Mg-MOF) synthesized by following the modified technique of Spanopoulos et al., (2015); and 7) zinc-2-methylimidazole zeolytic type MOF (ZIF-8-MOF) synthesized according to Park et al., (2006). The synthesized MOFs (around 100 g for each) were put in colored glasses, capped and stored at ambient temperature during the study. The morphology and structural properties, surface and pore properties, thermal properties, spectral properties and adsorption properties of the synthesized MOFs were previously studied in our laboratory and published (Yilmaz et al., 2018). The abbreviated MOF names given in the brackets are used throughout the paper hereafter.

All other chemicals and standards were purchased from Sigma (St. Louis, US), Merck (Darmstad, Germany) Chem. Co., and local stores.

2.2. Adsorbent treatments of the degummed crude sunflower oilTOP

There were 4 treatment groups based on the two adsorbent addition levels (0.05% and 0.3%, w/w) and two treatment times (0.5 h and 3.0 h). All treatments were completed at 25 °C, and temperature was not a factor in this study. Degummed crude sunflower oil was portioned into 150 ml samples, and each of the adsorbents at the given addition level was added into the oil, and mixed for the given time in an orbital shaker at 250 rpm at 25 °C. After the treatment, the slurry was filtered through Whatman no. 40 paper, and the collected oil samples were put into colored glasses, flushed with nitrogen, capped tightly, and stored in the refrigerator during the analyses. A control sample was treated in the same way without adsorbent. All treatments were repeated twice, and each oil sample was analyzed twice.

2.3. Physical analyses of the treated oil samplesTOP

The instrumental color parameters of L, a* and b* were recorded with a Minolta Colorimeter CR-400 (Minolta Camera Co., Osaka, Japan) by the technique of Aydeniz and Yilmaz (2016). An Abbe 5 (Bellingham and Stanley, UK) refractometer at 25 °C was used to assess the refractive indices of the oil samples. Turbidity values were measured with s Hach 2100 AN Turbidimeter (USA) at 25 °C (Aydeniz and Yilmaz, 2016).

2.4. Chemical analyses of the treated oil samplesTOP

Free fatty acids as % linoleic acid, peroxide values as meqO2/kg, p-anisidine values and unsaponifiable matter contents (%) of the oil samples were measured according to Ca 5a-40, Cd 8-53, Cd 18-90 of AOCS (AOCS, 1998), and TSE 894 method (TSE, 1970), respectively. The α-tocopherol compositions of the oil samples were analyzed by the method of Grilo Câmara et al., (2014), and Aydeniz and Yilmaz (2016) with a reverse-phase HPLC (Shimadzu Corporation, Kyoto, Japan) equipped with a LC-20AT HPLC pump, DGU-20A5R degasser, CTQ-10ASVP column oven, and RF-20A diode array detector.

2.5. Mineral compositions of the treated oil samplesTOP

The oil samples were prepared according to the wet burning process applied in a microwave burner (Berghof speed wave v1.2.2 506) through mixing 0.5 g oil sample with 7 mL HNO3 and 3 mL HCI under a gradual heating process (50 °C - 5 min, 150 °C - 10 min, 200 °C - 20 min, 200 °C - 10 min, 200 °C - 10 min) until clear in color. The clear solution was then completed to 50 ml with distilled-deionized water before the mineral content analysis with an ICP-OES Spectrometer (Perkin Elmer Optima 8000, Boston, US) with appropriate dilutions of AccuTrace reference standards (New Haven, USA) for curve calibration. The method of Yilmaz et al., (2017) was followed for the analysis.

2.6. Sterol compositions of the treated oil samplesTOP

The ISO 12228 method (ISO, 1999) was followed for the determination of the sterols in the treated oil samples. First, the unsaponifiable matters were extracted from the oil and then the sterol fractions were separated by TLC. Finally, the sterol fractions were analyzed on a Gas Chromatograph-FID (Agilent Technologies 7890B, Palo Alto, CA, US) with a DB5 capillary column (30 m × 0.25mm ID × 0.1 μm film thickness, J&W Scientific Co, CA, US). The GC conditions were as follows: 1 µl injection volume; 1:100 injector split ratio; 0.8 ml/min flow rate; hydrogen as carrier gas; hydrogen (30 ml/min) and dry air (400 ml/min) as detector gasses; 290 °C inlet temperature and 300 °C detector temperature. The oven temperature program was as follows: 60 °C for 2 min; 220 °C (40 °C/min) for 1 min; 310 °C (5 °C/min) for 30 min. Commercial standards were used to identify the sterols, and the peak area of α-cholestanol, added into the sample as internal standard, was used to quantify the identified sterols.

2.7. Fatty acid compositions of the treated oil samplesTOP

The fatty acid compositions of the oil samples were determined with an Agilent 7890B gas chromatograph (Agilent Technologies, Palo Alto, CA, US) equipped with a HP 88 (100 m×0.25 mm, 0.2 μm) capillary column, Agilent G4513A autosampler and FID detector, according to the method Ce 1-62 (AOCS, 1998), and after the preparation of the fatty acid methyl esters according to the method Ce 2-66 (AOCS, 1998) using methanolic KOH. The carrier gas was hydrogen at a flow rate of 2 mL/min, and split ratio of 1/50. The injection volume was 1 µl. The detector was set at 280 °C with hydrogen 40 ml/min and dry air 450 ml/min, and the injector was set at 250 °C. The oven temperature program was as follows; held at 120 °C for 1 min; raised to 175 °C at a rate of 10 °C/min and then held at this temperature for 10 min; raised to 210 °C at a rate of 5 °C/min and held at this temperature for 5 min; raised to 230 °C at a rate of 5 °C/min, and held at this temperature for 5 min. The 37-component FAME mix (C4-C24; Supelco, Prep-Inc.) was used for fatty acid identification.

2.8. Recycling study of the selected adsorbentsTOP

Based on the previous analytical results, Ti-MOF, γ-CD-MOF and sepiolite were selected for the recycling study. After the first treatment of the degummed crude sunflower oil with the adsorbents at 0.3% addition level for 3.0 h mixing at 25 °C, the used adsorbents were filtered, and regenerated by washing with hexane 3 times (10 mL each) and ethanol 3 times (10 mL each), before drying under vacuum at 150 °C for 4 h. Then, each regenerated adsorbent was reused five consecutive times under the same conditions as the first treatment to observe the recovery capacity. After five treatments, the collected oil samples were analyzed for free acids, peroxide value and p-anisidine value.

2.9. Statistical analysisTOP

The whole study was repeated twice, and all analyses within each replicate samples were performed at least two times. Significant differences among the samples were determined by the one-way ANOVA with means separation by Tukey’s test at a 95% level of confidence with the Minitab (Minitab, 2010) statistics program.

3. RESULTS AND DISCUSSIONTOP

3.1. Comparison of the adsorbents and treatment conditionsTOP

The physico-chemical analyses results of the oil samples treated with the seven selected MOFs and three natural clays at the two different addition levels (0.05% and 0.3%) and two different treatment times (0.5 h and 3.0 h) are presented in Tables 1, 2, 3 and 4, respectively. In all treatments, the temperature was constant at 25 °C. These tables provide the opportunity to compare the different adsorbent materials for each treatment condition along with general insight into the best treatment parameters. The selection of the two addition levels and the two treatment times were based on common industrial applications, where most of the oil refining facilities worldwide use 0.15–3.5% adsorbent addition levels and 0.5–3.5 h treatment times (Hodgson, 1996; Nas and Gokalp, 2017). Since in the only MOF study on edible oil purification published (Vlasova et al., 2016), 25 °C was suggested as the main advantage of MOF application, that temperature was selected as the constant parameter for all treatments in this study. It was stated that in most industrial bleaching applications the applied temperature range is between 85 and 110 °C (Hodgson, 1996; Nas and Gokalp, 2017). Currently, only one study (Vlasova et al., 2016) presented the results of 3 different MOFs; while in this study 7 different MOFs were used and 3 natural clays were tested under the same conditions for comparison to provide new information.

Table 1. The Physico-Chemical Properties of the Crude Sunflowerseed Oil Treated with MOFs and Natural Clays at 25 °C for 0.5 h with 0.05% (w/w) Addition Level.

| |

L value |

a* value |

b* value |

Refractive index |

Turbidity (NTU) |

Free acidity (linoleic acid %) |

Peroxide value (meqO2/kg)

|

p-Anisidine value |

| Control |

25.50±0.96d*

|

−0.37±0.13a |

5.00±1.81d |

1.47±0.00a |

92.93±0.61a |

2.50±0.14a |

25.02±0.07a |

1.61±0.11a |

| Ti-MOF |

30.16±0.15c |

−1.49±0.01bc |

10.64±0.62bc |

1.47±0.00a |

9.75±0.77c |

2.22±0.05a |

21.76±0.72cd |

1.40±0.05a |

| γ-CD-MOF |

30.59±0.04c |

−1.59±0.14bc |

9.74±0.87c |

1.47±0.00a |

1.24±0.14h |

2.12±0.15a |

20.02±0.28d |

1.30±0.02a |

| Cr-MOF |

31.57±0.26abc |

−1.83±0.02cd |

12.36±0.11abc |

1.47±0.00a |

7.08±0.58d |

2.19±0.24a |

23.10±0.07ab |

1.49±0.11a |

| Al-MOF |

29.96±1.01c |

−1.35±0.79b |

9.73±1.31c |

1.47±0.00a |

14.52±0.55b |

2.20±0.15a |

23.14±0.05bc |

1.48±0.16a |

| Zn-MOF |

32.65±0.04ab |

−1.99±0.00d |

13.62±0.01ab |

1.47±0.00a |

3.66±0.59ef |

2.17±0.19a |

23.26±0.28bc |

1.50±0.24a |

| Mg-MOF |

31.13±0.82bc |

−1.51±0.87bc |

10.23±0.07c |

1.47±0.00a |

4.05±0.21e |

2.17±0.18a |

21.99±0.41bc |

1.41±0.18a |

| ZIF-8-MOF |

31.39±0.54abc |

−1.64±0.04bc |

11.32±0.34abc |

1.47±0.00a |

1.54±0.29gh |

2.23±0.05a |

22.26±0.73bc |

1.44±0.06a |

| C.B.E. |

33.05±0.62abc |

−2.15±0.07bc |

13.82±0.68a |

1.47±0.00a |

1.75±0.20gh |

2.23±0.06a |

22.51±0.23bc |

1.45±0.05a |

| Zeolite |

32.69±0.34ab |

−2.07±0.02d |

13.68±0.29ab |

1.47±0.00a |

1.53±0.27gh |

2.22±0.26a |

22.26±0.39bc |

1.44±0.43a |

| Sepiolite |

33.14±0.16a |

−2.16±0.01d |

14.13±0.01a |

1.47±0.00a |

2.66±0.66fg |

2.22±0.15a |

21.76±0.72cd |

1.40±0.31a |

NTU: nephelometric turbidity unit, MOF: metal-organic framework, Ti: titanium, γ-CD: gamma-cyclodextrine, Cr: cromium, Al: aluminum, Zn: zinc, Mg: magnesium, ZIF-8: zeolitic type 8, C.B.E.: commercial bleaching earth.

*Small uppercase letters indicate the statistically significant differences within each column for the mean ± SD values calculated from four determinations by one-way ANOVA and Tukey’s test (p ≤ 0.05). |

Table 2. The Physico-Chemical Properties of the Crude Sunflowerseed Oil Treated with MOFs and Natural Clays at 25 °C for 0.5 h with 0.3% (w/w) Addition Level.

| |

L value |

a* value |

b* value |

Refractive index |

Turbidity (NTU) |

Free acidity (linoleic acid %) |

Peroxide value (meqO2/kg)

|

p-Anisidine value |

| Control |

25.50±0.96e*

|

−0.37±0.13a |

5.00±1.81c |

1.47±0.00a |

92.93±0.61a |

2.50±0.14a |

25.02±0.07a |

1.61±0.11a |

| Ti-MOF |

29.73±0.69d |

−1.11±0.07b |

10.31±1.04bc |

1.47±0.00a |

37.90±0.14b |

1.44±0.45a |

16.19±0.42de |

1.05±0.12ab |

| γ-CD-MOF |

32.50±0.80a |

−2.37±0.12de |

12.83±0.77ab |

1.47±0.00a |

1.69±0.42fg |

1.45±0.25a |

15.75±0.29de |

1.01±0.04b |

| Cr-MOF |

30.73±0.30cd |

−1.66±0.07c |

10.60±1.12ab |

1.47±0.00a |

19.85±0.63d |

1.55±0.26a |

16.66±0.43cde |

1.07±0.02ab |

| Al-MOF |

32.22±0.39ab |

−1.92±0.05c |

13.13±0.51a |

1.47±0.00a |

27.90±0.70c |

1.45±0.32a |

17.51±0.70bc |

1.13±0.20ab |

| Zn-MOF |

32.41±0.36ab |

−2.02±0.04cd |

13.61±0.28a |

1.47±0.00a |

1.69±0.52fg |

1.55±0.32a |

18.18±0.02b |

1.18±0.13ab |

| Mg-MOF |

30.89±0.31bc |

−1.69±0.07c |

10.68±0.32ab |

1.47±0.00a |

6.16±0.04e |

1.52±0.41a |

16.36±0.15cde |

1.05±0.23ab |

| ZIF-8-MOF |

32.00±0.19abc |

−1.88±0.04c |

12.32±0.23ab |

1.47±0.00a |

7.34±0.74e |

1.54±0.18a |

16.79±0.12cd |

1.08±0.41ab |

| C.B.E. |

33.40±0.21a |

−2.54±0.02e |

13.74±0.25a |

1.47±0.00a |

1.12±0.05g |

1.51±0.24a |

16.64±0.18cde |

1.08±0.16ab |

| Zeolite |

32.26±0.94ab |

−1.96±0.94c |

12.68±1.50ab |

1.47±0.00a |

2.08±0.71fg |

1.47±0.19a |

16.24±0.32cde |

1.04±0.42ab |

| Sepiolite |

33.33±0.36a |

−2.44±0.36e |

13.81±0.60a |

1.47±0.00a |

2.84±0.98f |

1.45±0.19a |

15.46±0.18e |

1.01±0.30b |

NTU: nephelometric turbidity unit, MOF: metal-organic framework, Ti: titanium, γ-CD: gamma-cyclodextrine, Cr: cromium, Al: aluminum, Zn: zinc, Mg: magnesium, ZIF-8: zeolitic type 8, C.B.E.: commercial bleaching earth.

*Small uppercase letters indicate the statistically significant differences within each column for the mean ± SD values calculated from four determinations by one-way ANOVA and Tukey’s test (p ≤ 0.05). |

Table 3. The Physico-Chemical Properties of the Crude Sunflowerseed Oil Treated with MOFs and Natural Clays at 25 °C for 3.0 h with 0.05% (w/w) Addition Level.

| |

L value |

a* value |

b* value |

Refractive index |

Turbidity (NTU) |

Free acidity (linoleic acid %) |

Peroxide value (meqO2/kg)

|

p-Anisidine value |

| Control |

25.50±0.96e*

|

−0.37±0.13a |

5.00±1.81d |

1.47±0.00a |

92.93±0.61a |

2.50±0.14a |

25.02±0.07a |

1.61±0.11a |

| Ti-MOF |

29.40±0.03e |

−1.19±0.04b |

9.23±0.17bc |

1.47±0.00a |

16.30±0.76b |

1.37±0.20b |

17.51±0.70b |

1.13±0.02a |

| γ-CD-MOF |

31.70±0.04a |

−1.89±0.03c |

12.47±0.02a |

1.47±0.00a |

1.24±0.02f |

1.45±0.19b |

18.19±0.60b |

1.18±0.05a |

| Cr-MOF |

29.79±0.45e |

−1.53±0.14bc |

9.74±0.49abc |

1.47±0.00a |

6.76±0.24d |

1.50±0.29b |

19.18±0.53b |

1.23±0.09a |

| Al-MOF |

31.21±0.14abc |

−1.64±0.16bc |

10.14±1.08ab |

1.47±0.00a |

9.16±0.21c |

1.50±0.25b |

18.76±0.76b |

1.20±0.16a |

| Zn-MOF |

30.46±0.12d |

−1.11±0.07ab |

6.14±0.64d |

1.47±0.00a |

1.65±0.28f |

1.30±0.16b |

18.20±0.43b |

1.17±0.23a |

| Mg-MOF |

31.37±0.35ab |

−1.61±0.43bc |

11.83±0.65a |

1.47±0.00a |

3.16±0.39e |

1.25±0.02b |

16.96±0.72b |

1.09±0.45a |

| ZIF-8-MOF |

30.41±0.02cd |

−1.52±0.05bc |

8.52±0.14bcd |

1.47±0.00a |

1.27±0.29f |

1.46±0.25b |

18.73±0.70b |

1.21±0.31a |

| C.B.E. |

30.71±0.25bcd |

−1.69±0.18bc |

10.56±0.46ab |

1.47±0.00a |

1.57±0.27f |

1.40±0.32b |

17.79±0.57b |

1.15±0.08a |

| Zeolite |

30.78±0.04bcd |

−1.58±0.07bc |

10.51±0.03ab |

1.47±0.00a |

3.10±0.37e |

1.49±0.14b |

19.05±0.26b |

1.23±0.21a |

| Sepiolite |

30.40±0.02d |

−1.35±0.05bc |

7.45±0.43cd |

1.47±0.00a |

1.31±0.25f |

1.41±0.07b |

18.37±0.49b |

1.17±0.18a |

NTU: nephelometric turbidity unit, MOF: metal-organic framework, Ti: titanium, γ-CD: gamma-cyclodextrine, Cr: cromium, Al: aluminum, Zn: zinc, Mg: magnesium, ZIF-8: zeolitic type 8, C.B.E.: commercial bleaching earth.

*Small uppercase letters indicate the statistically significant differences within each column for the mean ± SD values calculated from four determinations by one-way ANOVA and Tukey’s test (p ≤ 0.05).

|

Table 4. The Physico-Chemical Properties of the Crude Sunflowerseed Oil Treated with MOFs and Natural Clays at 25 °C for 3.0 h with 0.3% (w/w) Addition Level.

| |

L value |

a* value |

b* value |

Refractive index |

Turbidity (NTU) |

Free acidity (linoleic acid %) |

Peroxide value (meqO2/kg)

|

p-Anisidine value |

| Control |

25.50±0.96f*

|

−0.37±0.13a |

5.00±1.81e |

1.47±0.00a |

92.93±0.61a |

2.50±0.14a |

25.02±0.07a |

1.61±0.11a |

| Ti-MOF |

28.33±0.14e |

−0.06±0.00a |

7.48±0.20e |

1.47±0.00a |

45.22±0.69b |

0.65±0.41b |

10.60±0.08d |

0.68±0.23b |

| γ-CD-MOF |

32.75±0.28bc |

−2.00±0.05cd |

13.77±0.34abc |

1.47±0.00a |

5.08±0.56ef |

0.77±0.22b |

11.62±0.43cd |

0.74±0.11b |

| Cr-MOF |

30.26±0.56d |

−1.61±0.11b |

11.09±0.79cd |

1.47±0.00a |

25.22±0.40c |

0.85±0.15b |

13.29±0.38b |

0.85±0.33b |

| Al-MOF |

33.07±0.28bc |

−2.14±0.28de |

14.01±0.28ab |

1.47±0.00a |

7.75±0.57d |

0.70±0.12b |

12.61±0.84bc |

0.82±0.52ab |

| Zn-MOF |

30.80±0.52d |

−1.60±0.08b |

10.40±0.35d |

1.47±0.00a |

1.43±0.29hı |

0.85±0.31b |

12.71±0.22bc |

0.83±0.18b |

| Mg-MOF |

30.95±0.15d |

−1.77±0.02bc |

11.87±0.28bcd |

1.47±0.00a |

5.26±0.75e |

0.87±0.06b |

13.37±0.45b |

0.87±0.19b |

| ZIF-8-MOF |

31.39±0.76d |

−1.80±0.23b |

10.40±0.35d |

1.47±0.00a |

1.21±0.19ı |

0.82±0.14b |

12.26±0.32bc |

0.78±0.33b |

| C.B.E. |

32.39±0.19c |

−2.49±0.35f |

11.81±0.08bcd |

1.47±0.00a |

3.87±0.37fg |

0.70±0.09b |

12.93±0.16bc |

0.83±0.05b |

| Zeolite |

33.12±0.42ab |

−2.23±0.06ef |

13.98±0.42ab |

1.47±0.00a |

2.67±0.51gh |

0.67±0.31b |

12.74±0.31bc |

0.82±0.08b |

| Sepiolite |

34.24±0.03a |

−2.80±0.03g |

14.64±0.24a |

1.47±0.00a |

3.01±0.87g |

0.75±0.14b |

13.48±0.50b |

0.86±0.09b |

NTU: nephelometric turbidity unit, MOF: metal-organic framework, Ti: titanium, γ-CD: gamma-cyclodextrine, Cr: cromium, Al: aluminum, Zn: zinc, Mg: magnesium, ZIF-8: zeolitic type 8, C.B.E.: commercial bleaching earth.

*Small uppercase letters indicate the statistically significant differences within each column for the mean ± SD values calculated from four determinations by one-way ANOVA and Tukey’s test (p ≤ 0.05).

|

With the low addition level (0.05%) and shorter treatment time (0.5 h), MOF treatments altered the color values of the oil samples compared with the control (Table 1). Enhancement in oil brightness was better with sepiolite and commercial bleaching earth (C.B.E) treatments than the MOFs. The values of a* also changed from a red color toward a more green direction as the negative value increased. Natural clays had a more pronounced effect than the MOFs as well. A similar trend was evident in the b* value, and after treatments, oil color became more yellow. There was no difference among the samples for the refractive indice values. Oil turbidity decreased significantly after the adsorbent treatments, and the most significant reduction was observed in the γ-CD-MOF treated sample. Although this treatment enhanced the L value, its effect on turbidity was the best among all of them. Hence, γ-CD-MOF might have a mechanism to effectively adsorb haziness materials from the oil. Compared to the control, a similar trend was evident for the peroxide value (PV) and p-anisidine value (p-AV), and γ-CD-MOF was the best among them all. Clearly at a low addition level, all MOFs and natural clays had some positive effects on oil quality parameters, but γ-CD-MOF was the best among them all.

Enhancing the addition level of the adsorbents to 0.3% and keeping the treatment time the same (0.5 h) yielded better results, especially for FFA, PV and p-AV (Table 2). Oil color values showed almost no change with just addition level increasements, while turbidity values were enhanced. This was quite interesting, and the opposite was only observed with the C.B.E. treatment. The FFA values were between 2.17 and 2.23% with the low addition level treatment (0.05% and 0.5 h), and decreased to 1.44 to 1.55% with the high addition level (0.3% and 0.5 h) treatment. This could be accepted as a significant enhancement. Similar enhancements were also measured with the high addition level for the PV (20.02–23.26 meqO2/kg and 15.46–18.18 meqO2/kg, respectively) and p-AV (1.30–1.50 and 1.01–1.18). Overall, enhancing adsorbent addition level while maintaining treatment times the same yielded better results, but it was worth observing the effect of the longer treatment time as well.

The longer treatment time, 3.0 h, was applied with both low addition level (0.05%) and high addition level (0.3%), and the findings are presented in Tables 3 and 4. The longer treatment time at low dosage (Table 3) resulted in better color values compared with the short time low dosage (Table 1) treatments. Enhancement of only the treatment time resulted in much better FFA (2.12–2.23 vs. 1.25–1.50%), PV (20.02–23.26 vs. 16.96–19.05 meqO2/kg), and p-AV (1.30–1.50 vs. 1.13–1.23) in comparison with short treatment time, respectively. Color and turbidity values were less affected by longer treatment time (Table 1 and Table 3).

The results of higher dosage (0.3%) and longer treatment time (3.0 h) are shown in Table 4. Clearly all the expected improvements were the highest in this treatment group (Table 4) compared to the others (Tables 1, 2 and 3). All adsorbent treatment changed the color values significantly compared to the control sample. Among the treatments, sepiolite and Al-MOF treatment had the largest effects on the color values. Hence, MOF treatments could improve the color values of crude oils, but these improvements were not better than the C.B.E and sepiolite. All adsorbent treatments caused some reduction in oil turbidity, but the highest decrease (1.21 NTU) was measured with ZIF-8-MOF compared to the control (92.93 NTU), while the lowest decrease was observed with Ti-MOF (45.22 NTU) (Table 4). Quite profound results were obtained with high dosage and longer treatment time (Table 4) compared to the others (Tables 1, 2 and 3) for FFA, PV and p-AV. Although all treatments decreased FFA compared to the control (2.50%), the effect of Ti-MOF was the best (0.65%). The same trends were also shown for PV (10.60 vs. 25.02 meqO2/kg) and p-AV (0.68 vs. 1.61) for the Ti-MOF sample in comparison with the control. Overall, as the addition level or dosage and treatment time increased, the expected positive results with the treatments increased. Clearly, for the chemical parameters, Ti-MOF provided the best results, and could be utilized for crude oil refining purposes.

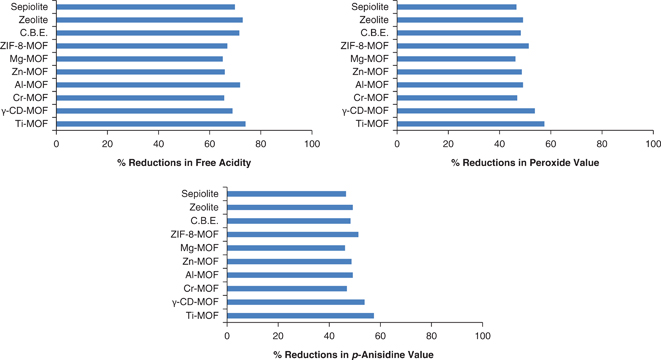

Percent reduction values over the control sample for crude sunflower seed oil treated with MOFs and natural clays at 25 °C for 3.0 h with 0.3% (w/w) addition level are presented in Figure 1 to observe and compare all adsorbents. Percent reduction in FFA was the highest with Ti-MOF (74.05%), followed by zeolite (72.90%). Vlasova et al., (2016) quantified a 64.8% reduction for FFA in sunflower oil with Ti-MOF, followed by 59.8% with Zn-MOF. Since the C.B.E in this study yielded a 71.60% reduction in FFA, only Ti-MOF, Al-MOF and zeolite exceeded this value and could be accepted as better. Similarly, the PV was reduced by around 57.60% by Ti-MOF, followed by 53.60% with γ-CD-MOF. Both MOFs were better than the C.B.E. In the study of Vlasova et al., (2016), the degree of extraction for PV in sunflower oil was 45.7% with Ti-MOF, but it was 93.4% with Ti-MOF for linseed oil. Clearly, Ti-MOF and γ-CD-MOF are quite good in removing peroxides from crude sunflower oil. The very same trend was evident (Figure 1) for p-AV with Ti-MOF and γ-CD-MOF, respectively. Overall, these results indicate that especially Ti-MOF and γ-CD-MOF would have value in the physical refining of crude oils.

|

Figure 1. Percent reduction values over the control sample for crude sunflowerseed oil treated with MOF and natural clays at at 25 °C for 3.0 h with 0.3% (w/w) addition level (MOF: metal-organic framework, Ti: titanium, γ-CD: gamma-cyclodextrine, Cr: cromium, Al: aluminum, Zn: zinc, Mg: magnesium, ZIF-8: zeolitic type 8, C.B.E.: commercial bleaching earth) Figure 1. Percent reduction values over the control sample for crude sunflowerseed oil treated with MOF and natural clays at at 25 °C for 3.0 h with 0.3% (w/w) addition level (MOF: metal-organic framework, Ti: titanium, γ-CD: gamma-cyclodextrine, Cr: cromium, Al: aluminum, Zn: zinc, Mg: magnesium, ZIF-8: zeolitic type 8, C.B.E.: commercial bleaching earth)

|

|

While, MOF applications to crude oil as adsorbents have created some good results in the oil’s physical and chemical properties, it was necessary to test what happened in oil composition, and whether any metal contamination occurred during the treatments from MOFs into the oil.

3.2. Effects of adsorbent treatments on oil componentsTOP

Since the best improvements in oil quality were achieved with higher dosage (0.3%) and longer treatment time (3.0 h), the same treatment conditions were selected to treat and analyze the oil samples for oil mineral, sterol and fatty acid compositions (Tables 5, 6, and 7) to observe any other possible effects of the adsorbent treatments. Further, these composition analyses were needed to establish the nutritional effects and safety value of the MOF adsorbent treatments.

Table 5. The Mineral Composition (mg/kg) of the Crude Sunflowerseed Oil Treated with MOFs and Natural Clays at at 25 °C for 3.0 h with 0.3% (w/w) Addition Level.

| |

Al |

Zn |

P |

Cr |

Mg |

K |

| Control |

132.80±0.11a*

|

15.38±0.14a |

43.68±0.47a |

1.22±0.00a |

1212±0.91a |

281.30±0.44a |

| Ti-MOF |

127.10±0.22b |

12.72±0.08d |

40.91±0.23b |

1.04±0.01b |

1113±15.25h |

243.40±1.10j |

| γ-CD-MOF |

70.34±0.32g |

7.05±0.02h |

30.39±0.41cd |

0.75±0.01d |

613.80±4.95f |

153.00±0.88f |

| Cr-MOF |

131.40±0.78a |

11.64±0.07e |

42.96±0.49a |

1.01±0.01b |

1203±24.67a |

266.90±1.35b |

| Al-MOF |

73.93±0.21f |

6.44±0.06ı |

30.65±0.62c |

0.72±0.02d |

661±3.02e |

155.70±0.28e |

| Zn-MOF |

71.49±0.21g |

8.09±0.03g |

30.27±0.39cd |

0.84±0.01cd |

604.60±3.10f |

147.00±0.03g |

| Mg-MOF |

38.51±0.33ı |

8.80±0.09f |

31.22±0.25c |

0.83±0.01d |

626.20±5.30f |

148.10±0.80g |

| ZIF-8-MOF |

62.29±0.44h |

8.98±0.02f |

29.07±0.31d |

0.84±0.01d |

548.70±7.01g |

131.90±0.62h |

| C.B.E. |

104±1.03d |

12.96±0.02d |

39.68±1.07b |

1.12±0.00ab |

1001±15.29c |

202.10±1.47d |

| Zeolite |

110.20±0.42c |

14.78±0.19b |

39.58±0.62b |

0.99±0.01bc |

1156±14.05b |

227.80±2.14c |

| Sepiolite |

81.44±0.24e |

13.99±0.02c |

33.17±0.58e |

0.85±0.02d |

747.50±16.73d |

168.60±0.61ı |

Al: aluminum, Zn: zinc, P: phosphorous, Cr: cromium, Mg: magnesium, K: potassium, Ti: titanium, γ-CD: gamma-cyclodextrine, ZIF-8: zeolitic type 8, MOF: metal-organic framework, C.B.E.: commercial bleaching earth.

*Small uppercase letters indicate the statistically significant differences within each column for the mean ± SD values calculated from four determinations by one-way ANOVA and Tukey’s test (p ≤ 0.05).

|

Table 6. The Sterol Composition (mg/100 g) and Unsaponifiable Matter Content of the Crude Sunflowerseed Oil Treated with MOFs and Natural Clays at at 25 °C for 3.0 h with 0.3% (w/w) Addition Level.

| |

Cholesterol |

Brassicasterol |

Campesterol |

Stigmasterol |

β-Sitosterol |

Δ-5-Avenasterol |

Unsaponifiable matter (%) |

| Control |

<0.5±0.08a*

|

1.80±0.01a |

20.20±0.05a |

28.30±0.05a |

186.40±0.04a |

19.40±0.24a |

1.16±0.09a*

|

| Ti-MOF |

<0.5±0.04a |

1.74±0.05a |

19.40±0.04a |

27.16±0.08a |

178.81±0.04a |

18.63±0.11a |

1.22±0.05a |

| γ-CD-MOF |

<0.5±0.07a |

1.72±0.08a |

19.33±0.19a |

27.10±0.28a |

178.15±0.07a |

18.61±0.16a |

1.17±0.02a |

| Cr-MOF |

<0.5±0.02a |

1.73±0.02a |

19.35±0.29a |

27.02±0.04a |

177.40±0.11a |

18.57±0.02a |

1.20±0.02a |

| Al-MOF |

<0.5±0.02a |

1.72±0.02a |

19.27±0.15a |

26.98±0.08a |

177.21±0.14a |

18.45±0.07a |

1.22±0.00a |

| Zn-MOF |

<0.5±0.05a |

1.70±0.04a |

19.08±0.19a |

26.63±0.05a |

175.12±0.07a |

18.27±0.21a |

1.19±0.04a |

| Mg-MOF |

<0.5±0.09a |

1.72±0.08a |

19.33±0.25a |

26.63±0.15a |

176.85±0.05a |

18.43±0.09a |

1.23±0.20a |

| ZIF-8-MOF |

<0.5±0.08a |

1.72±0.07a |

19.40±0.24a |

26.82±0.05a |

176.13±0.08a |

18.40±0.11a |

1.16±0.05a |

| C.B.E. |

<0.5±0.11a |

1.70±0.04a |

18.99±0.21a |

26.61±0.05a |

175.08±0.24a |

18.24±0.11a |

1.29±0.10a |

| Zeolite |

<0.5±0.07a |

1.71±0.01a |

19.10±0.28a |

26.78±0.15a |

175.87±0.04a |

18.29±0.26a |

1.21±0.02a |

| Sepiolite |

<0.5±0.11a |

1.70±0.02a |

19.03±0.18a |

26.72±0.11a |

175.23±0.16a |

18.35±0.32a |

1.24±0.02a |

MOF: metal-organic framework, Ti: titanium, γ-CD: gamma-cyclodextrine, Cr: cromium, Al: aluminum, Zn: zinc, Mg: magnesium, ZIF-8: zeolitic type 8, C.B.E.: commercial bleaching earth.

*Small uppercase letters indicate the statistically significant differences within each column for the mean ± SD values calculated from four determinations by one-way ANOVA and Tukey’s test (p ≤ 0.05).

|

Table 7. The Fatty Acid (%) and α-Tocopherol (mg/kg) Composition of the Crude Sunflowerseed Oil Treated with MOFs and Natural Clays at at 25 °C for 3.0 h with 0.3% (w/w) Addition Level.

| |

Palmitic acid |

Stearic acid |

Oleic acid |

Linoleic acid |

α-Tocopherol |

| Control |

6.87±0.02a |

4.42±0.01a |

33.50±0.04a |

55.21±0.03a |

142.22±0.74a |

| Ti-MOF |

7.08±0.12a |

4.03±0.03a |

33.68±0.08a |

55.07±0.06a |

138.88±0.38b |

| γ-CD-MOF |

7.54±0.13a |

4.40±0.12a |

32.98±0.09a |

55.07±0.08a |

128.41±0.48e |

| Cr-MOF |

6.97±0.22a |

4.35±0.22a |

33.47±0.02a |

55.20±0.11a |

124.65±0.18f |

| Al-MOF |

7.23±0.31a |

4.14±0.04a |

33.46±0.04a |

55.16±0.15a |

141.36±0.42a |

| Zn-MOF |

7.60±0.04a |

4.38±0.11a |

33.00±0.10a |

55.01±0.06a |

129.84±0.20d |

| Mg-MOF |

6.58±0.06a |

4.39±0.05a |

33.68±0.12a |

55.18±0.05a |

130.20±0.11d |

| ZIF-8-MOF |

7.25±0.08a |

4.26±0.06a |

33.30±0.18a |

55.18±0.02a |

142.14±0.46a |

| C.B.E. |

7.01±0.10a |

4.38±0.08a |

33.62±0.20a |

54.98±0.04a |

130.63±0.35d |

| Zeolite |

7.18±0.02a |

4.37±0.03a |

33.55±0.14a |

54.89±0.07a |

133.57±0.73c |

| Sepiolite |

7.32±0.03a |

4.28±0.03a |

33.68±0.05a |

54.71±0.18a |

124.91±0.06f |

MOF: metal-organic framework, Ti: titanium, γ-CD: gamma-cyclodextrine, Cr: cromium, Al: aluminum, Zn: zinc, Mg: magnesium, ZIF-8: zeolitic type 8, C.B.E.: commercial bleaching earth.

*Small uppercase letters indicate the statistically significant differences within each column for the mean ± SD values calculated from four determinations by one-way ANOVA and Tukey’s test (p ≤ 0.05).

|

Since MOFs are synthesized materials composed of different metal cores, it was worth determining whether any metal ion leaches into the oil during treatment. After the adsorbent treatments, 6 minerals were analyzed in the oil samples (Table 5). The Al content of all treated oils was significantly lower than the control sample, except for the Cr-MOF treated sample. Apparently, the Mg-MOF treated sample had the lowest Al content (38.51 mg/kg), followed by ZIF-8-MOF (62.29 mg/kg). Even in the Al-MOF treated sample, the content of Al (73.93 mg/kg) was lower than that of the control sample (132.80 mg/kg). Clearly, except Cr-MOF, all adsorbents removed some Al from the oil. The Zn content of the treated samples was significantly lower than the control, and the most effective treatment was with Al-MOF. Although not as much as the other minerals, some amounts of P were also removed by the adsorbents. ZIF-8-MOF was the most effective for P adsorption. The control sample had 1.22 mg/kg Cr, and the oil sample treated with Cr-MOF had only 1.01 mg/kg Cr remaining. Clearly, all adsorbents removed some Cr from the oil. The control oil had 1212 mg/kg Mg, and the ZIF-8-MOF treated sample had around 548.70 mg/kg Mg, indicating that some Mg from the oil sample was removed by the adsorbents. Lastly, K was also adsorbed by the adsorbents from the oil, and again ZIF-8-MOF was the most effective one. Overall, there was no metal leaching from the MOF structures into the oil, rather some minerals were removed from oil through adsorption onto the adsorbents; hence, MOFs could be safe in terms of metal contamination. The same result was indicated in the study of Vlasova et al., (2016).

The unsaponifiable matter contents and sterol compositions of the oil samples are presented in Table 6. There was no statistically important difference among the unsaponifiable contents of the samples; hence, these matters were not adsorbed significantly into the adsorbents. Six different sterols were quantified in the oil samples. Cholesterol content was lower than 0.5 mg/100 g, and there was no difference among the samples. Although brassicasterol was a little lower in the treated samples (1.70–1.74 mg/100 g) than the control sample (1.80 mg/100 g), none was statistically significant. Very similar data were presented for campesterol, stigmasterol, β-sitosterol and ∆-5-avenasterol. Obviously, none of the adsorbents had any affinity towards the sterols found in the crude degummed sunflower oil. This result could be credited very well, since phytosterols are health beneficial bioactive molecules and current trend tends to keep them as much as retained in the refined oils. The ranges of sterols in mid-oleic sunflower oil in codex standard (Codex, 1999) were given as: cholesterol 0.1–0.2%; brassicasterol 0.0–0.1%; campesterol 9.1–9.6%; stigmasterol 9.0–9.3%; β-sitosterol 56–58%; ∆-5-avenasterol 4.8–5.3%; ∆-7-stigmastenol 7.7–7.9%; ∆-7-avenasterol 4.3–4.4%; others 4.3–4.4%. The detected sterols were higher in the degummed crude mid-oleic sunflower oil samples in this study than the given values in the codex standard. Since the standard gives the sterols of fully refined oil, this difference could be due to the losses during chemical refining processes. The study of Vlasova et al., (2016) did not test the effects of MOF treatment on sterols, and this study provides this very essential information for the literature.

The fatty acid compositions and α-tocopherol contents of the oil samples are presented in Table 7. Four fatty acids were quantified in the samples as palmitic acid (6.58–7.60%), stearic acid (4.03–4.42%), oleic acid (33.00–33.68%), and linoleic acid (54.71–55.20%). There was no statistically significant difference among the samples for any fatty acids. Hence, clearly, adsorbent treatment did not cause any change in the fatty acid composition of the crude sunflower oil. Further, the fatty acid compositions of the oil samples were in accordance with the fatty acid composition of mid-oleic sunflower oil given in the standard (Codex, 1999).

Only the α-tocopherol contents of the oil samples were measured and compared (Table 7). There were some reductions after the adsorbent treatments. The control sample had 142.22 mg/kg α-tocopherol, and it was around 124.65 mg/kg in the Cr-MOF treated sample, the lowest among all the treated samples. Hence, both MOFs and natural clays have affinity for tocopherols, and some losses may occur. Tocopherol enrichment to this oil could be suggested after applying an adsorbent treatment. The codex standard (Codex, 1999) indicated 488–668 mg/kg α-tocopherol for mid-oleic sunflower oil, and this amount is fairly higher than those quantified in the samples in this study. This might be due to material differences or methodological differences.

Generally, adsorbent treatment has not created large differences among the samples for major and some minor components in the oil. This could be credited as a good finding. As usual in the sunflower oil industry, tocopherol enrichment, if needed, could be applied after adsorbent treatments. Since there was no mineral leaching, MOF applications could be accepted as safe and not detrimental to nutritive value.

3.3. Recycling abilities of the selected adsorbentsTOP

Based on the results discussed in the previous sections, 3 adsorbents (Ti-MOF, γ-CD-MOF and sepiolite) were selected for a recycling study, and five consecutive usages of standard adsorption procedure were accomplished. The collected oil samples were tested for FFA, PV and p-AV (Table 8) as the most important oil quality monitor parameters. As a very important property, oil FFA was 0.69% after the first application of Ti-MOF, and it was 0.79% after five consecutive uses of the same MOF. If the performance accepted as 100% was for the first usage, clearly 90% of initial activity remained after five cyclings. Similarly, after five times cycling, 91% and 65% of the initial activities remained for γ-CD-MOF and sepiolite for FFA removal ability, respectively. Hence, γ-CD-MOF is much more stable and regenerates more effectively than natural clay. This, in turn, indicates the reusability of MOF materials to lower the cost of their applications. For PVs, the recovery rate after five cycles was 87%, 86%, and 36% for Ti-MOF, γ-CD-MOF and sepiolite, respectively. Further, total reduction was always higher with Ti-MOF than those of the two others, indicating that for the removal of peroxides from oil Ti-MOF is better and could be used successfully up to five times, after washing and drying. Similarly, remaining p-AV reduction activities after five cyclings were 90%, 90%, and 56% for Ti-MOF, γ-CD-MOF, and sepiolite, respectively. A similar result was published for Al-MOF in the study of Vlasova et al., (2016), where up to five recycling times were viable. Overall, MOFs and particularly Ti-MOF was quite recyclable, and could be used up to five times without any large activity loss.

Table 8. The Recycling Abilities of the Selected Adsorbents by Five Times Use.

| Recycling Time |

Free acidity (linoleic acid %) |

| Ti-MOF |

γ-CD-MOF |

Sepiolite |

| First |

0.69±0.19 |

0.80±0.24 |

0.78±0.57 |

| Second |

0.72±0.29 |

0.82±0.38 |

0.88±0.07 |

| Third |

0.75±0.08 |

0.85±0.11 |

0.97±0.16 |

| Fourth |

0.78±0.24 |

0.87±0.45 |

1.08±0.56 |

| Fifth |

0.79±0.03 |

0.89±0.17 |

1.13±0.20 |

| |

Peroxide value (meqO2/kg) |

| First |

10.64±0.76 |

11.67±0.18 |

13.52±0.57 |

| Second |

10.67±0.19 |

11.72±0.32 |

13.58±0.07 |

| Third |

10.71±0.22 |

11.74±0.36 |

13.72±0.16 |

| Fourth |

10.76±0.04 |

11.77±0.11 |

13.80±0.56 |

| Fifth |

10.77±0.23 |

11.81±0.32 |

13.89±0.20 |

| |

p-Anisidine value |

| First |

0.62±0.10 |

0.73±0.14 |

0.92±0.28 |

| Second |

0.65±0.41 |

0.76±0.08 |

0.98±0.23 |

| Third |

0.69±0.33 |

0.78±0.16 |

1.13±0.52 |

| Fourth |

0.71±0.28 |

0.80±0.34 |

1.22±0.34 |

| Fifth |

0.72±0.45 |

0.83±0.28 |

1.36±0.03 |

Ti-MOF: titanium-metal-organic framework,

γ-CD-MOF: gamma-cyclodextrine metal-organic framework |

4. CONCLUSIONSTOP

In this study, the adsorptive activities of seven laboratory-synthesized MOFs were determined and compared with 3 natural clays for the refining of crude degummed sunflower oil. According to our knowledge, some of the MOFs were evaluated for the first time in this study for this purpose according to our knowledge. The effects of MOF treatment on the oil’s physico-chemical properties and oil compositions as well as metal leaching possibilities were tested. The results showed that especially Ti-MOF and γ-CD-MOF presented certain potential to improve the color and turbidity of crude sunflower oil. Most importantly, these MOFs yielded good ability to remove FFAs and peroxide compounds from the oil. Further, there was no metal ion leaching from the MOFs into the oil during the treatment, and hence, the application can be credited as safe for metal contamination risks. Moreover, MOF application did not change the fatty acid composition of the oil, nor did it decrease the beneficial sterol components significantly. However, some losses in α-tocopherol occurred, and hence, tocopherol enrichment to this oil is suggested after adsorbent treatments. The MOFs, especially Ti-MOF and γ-CD-MOF were effective and easily regenerable adsorbents compared to the traditional natural clay sepiolite. They were regenerated up to five times without any large activity loss, and can therefore be recycled. The encouraging results of this study are expected to encourage new studies with other MOFs as adsorbent materials for crude edible oil purification purposes. In particular, synthesis chemists could design new MOF structures with selected and/or higher affinity towards aimed substances like FFA, pigments or peroxides to be used in oil purifications.

ACKNOWLEDGEMENTSTOP

This study was funded by the TUBITAK (The Scientific and Technological Research Council of Turkey) with Project No: 215O348, and the authors wish to thank them for their support. We would also like to thank Trakya Birlik Oil Processing Factory (Çorlu, Tekirdağ), Rota Mines Co. (İstanbul), and Madkim Coal and Chem. Co. (İstanbul).

REFERENCESTOP

| ○ |

Anonymous. 2018. Vegetable oil statistics of Turkey. http://www.bysd.org.tr/tr/istatistikler (Accessed in 27.06.2018)

|

| ○ |

AOCS. 1998. Official Methods and Recommended Practices of the American Oil Chemists’ Society, 5th Edn, AOCS Press, Champaigne 1998, IL.

|

| ○ |

Aydeniz B, Yılmaz E. 2016. Performance of different natural antioxidant compounds in frying oils. Food Technol. Biotechnol. 54, 21–30. https://doi.org/10.17113/ftb.54.01.16.4109 |

| ○ |

Bu F, Lin Q, Zhai Q, Wang L, Wu T, Zheng S-T, Bu X, Feng P. 2012. Two zeolite-type frameworks in one metal-organic framework with Zn24@Zn104 cube-in-sodalite architecture. Angew. Chem. Int. Ed. 51, 8538–8541. https://doi.org/10.1002/anie.201203425 |

| ○ |

Bulut E, Yilmaz E. 2010. Comparison of the frying stability of sunflower and refined olive pomace oils with/without adsorbent treatment. J. Am. Oil Chem. Soc. 87, 1145–1153.https://doi.org/10.1007/s11746-010-1605-y |

| ○ |

Codex. 1999. Codex standard for named vegetable oils, CXSTAN 210. Turkish Food Codex, Ankara, Turkey. |

| ○ |

Davidson HF, Campbell EJ, Bell RJ, Pritchard RA. 1996. Sunflower oil, in Hui YH. (Ed.) Bailey’s Industrial Oil and Fat Products, Wiley-Interscience, New York, pp. 603–690.

|

| ○ |

Dhakshinamoorthy A, Li Z, Garcia H. 2018. Catalysis and photocatalysis by metal organic frameworks. Chem. Soc. Rev. 47, 8134–8172. https://doi.org/10.1039/c8cs00256h |

| ○ |

Furukawa H, Cordova K, Keeffe M, Yaghi O. 2013. The chemistry and applications of metal-organic frameworks. Sci. 341 (6149), 123–444. https://doi.org/10.1126/science.1230444 |

| ○ |

Grilo Câmara E, Costa PN, Gurgel CSS, Beserra AFM, Almeida FNS, Dimenstein R. 2014. Alpha-tocopherol and gamma-tocopherol concentration in vegetable oils. Food Sci.Technol. (Campinas) 34, 379–385. https://doi.org/10.1590/S0101-20612014005000031 |

| ○ |

Hodgson AS. 1996. Refining and bleaching, in Hui, YH. (Ed.) Bailey’s Industrial Oil and Fat Products, Wiley-Interscience, New York, pp. 157–212.

|

| ○ |

Li N, Wang Z, Zhang L, Nian L, Lei L, Ynag X. 2014. Liquid-phase extraction coupled with metal-organic frameworks-based dispersive solid phase extraction of herbicides in peanuts. Talanta 128, 345–353. https://doi.org/10.1016/j.talanta.2014.04.084 |

| ○ |

Li N, Zhang L, Nian L, Cao B, Wang Z, Lei L, Yang X, Sui J, Zhang H, Yu A. 2015. Dispersive micro-solid-phase extraction of herbicides in vegetable oil with metal-organic framework MIL-101. J. Agric. Food Chem. 63, 2154–2161. https://doi.org/10.1021/jf505760y |

| ○ |

Ma Y, Lin J, Xue Y, Li J, Huang Y, Tang C. 2014. Acid-assisted hydro thermal synthesis and adsorption properties of high-specific-surface metal-organic frameworks. Mater. Lett. 132, 90–93.https://doi.org/10.1016/j.matlet.2014.06.025 |

| ○ |

Minitab. 2010. Minitab Statistical Software (Version 16.1.1). Minitab Inc. State College, Pennsylvania. |

| ○ |

Moussa Z, Hmadeh M, Abiad MG, Dib OH, Patra D. 2016. Encapsulation of curcumin in cycodextrin-metal organic frameworks: Dissociation of loaded CD-MOFs enhances stability of curcumin. Food Chem. 212, 485–494. https://doi.org/10.1016/j.foodchem.2016.06.013 |

| ○ |

Nas S, Gökalp HY. 2017. Bitkisel yağ teknolojisi (Vegetable oil technology). Sidas Medya Co, İzmir, Turkey, 320 p. ISBN: 978-605-5267-41-4. |

| ○ |

ISO. 1999. International Standards Official Methods 12228:1999. Animal and Vegetable Fats and Oils-Determination of Individual and Total Sterols Contents-Gas Chromatographic Method, International Organization for Standardization, Geneve, Switzerland.

|

| ○ |

Park KS, Ni Z, Cote AP, Choi JY, Huang R, Uribe-Romo FJ, Chae HK, O’Keeffe M, Yaghi O. 2006. Exceptional chemical and thermal stability of zeolitic imidazolate frameworks. Proc. Nat. Acad. Sci. USA. 103, 10186–10191. https://doi.org/10.1073/pnas.0602439103 |

| ○ |

Spanopoulos I, Bratsos I, Tampaxis C, Kourtellaris A, Tasiopoulos A, Charalambopoulou G, Steriotis TA, Trikalitis PN. 2015. Enhanced gas-sorption properties of a high surface area, ultra micro porous magnesium formate. Cryst. Eng. Comm. 17, 532–539. https://doi.org/10.1039/C4CE01667J |

| ○ |

Stock N, Biswas S. 2012. Synthesis of metal-organic frameworks (MOFs): routes to various MOF topologies, morphologies, and composites. Chem. Rev. 112, 933–969. https://doi.org/10.1021/cr200304e |

| ○ |

TSE. 1970. Yemeklik bitkisel yağlar-muayene metodları. Metot TSE 894. Resmi Gazete, Ankara, Turkey. |

| ○ |

Vlasova EA, Yakimov SA, Naidenko EV, Kudrik EV, Makarov SV. 2016. Application of metal-organic frameworks for purification of vegetable oils. Food Chem. 190, 103–109. https://doi.org/10.1016/j.foodchem.2015.05.078 |

| ○ |

Yilmaz E, Erden A, Güner M. 2018. Structure and properties of selected metal organic frameworks as adsorbent materials for edible oil purification. Riv. Ital. Del. Sost. Gras. 96, 25–38. ISSN: 0035-6808. ISSN: 0035-6808.

|

| ○ |

Yilmaz E, Hüriyet Z, Arifoğlu N, Dündar Emir D. 2017. Functional properties of the capia pepper seed defatted presscakes.

Waste Biomass Valor. 8, 783–791. https://doi.org/10.1007/s12649-016-9602-5 |

Figure 1. Percent reduction values over the control sample for crude sunflowerseed oil treated with MOF and natural clays at at 25 °C for 3.0 h with 0.3% (w/w) addition level (MOF: metal-organic framework, Ti: titanium, γ-CD: gamma-cyclodextrine, Cr: cromium, Al: aluminum, Zn: zinc, Mg: magnesium, ZIF-8: zeolitic type 8, C.B.E.: commercial bleaching earth)